Manufacturing Units

Design Activities

-

01

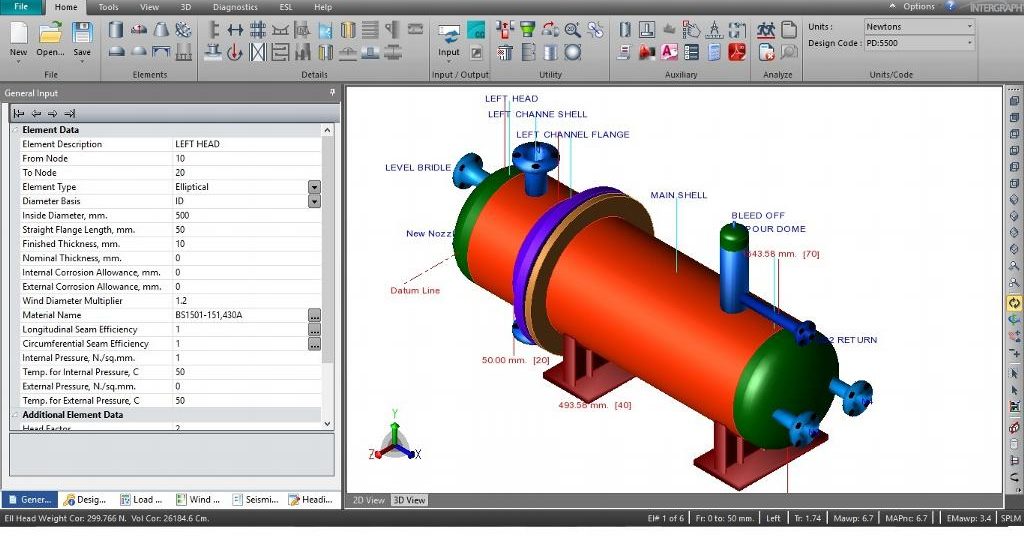

PV Elite Latest Version - for carrying out mechanical design calculations of ‘U’ stamp Pressure Vessels and Heat Exchangers.

-

02

AutoCAD Latest Version - for drafting of all equipment.

-

03

AutoCAD Latest Version - for drafting of all equipment.

-

04

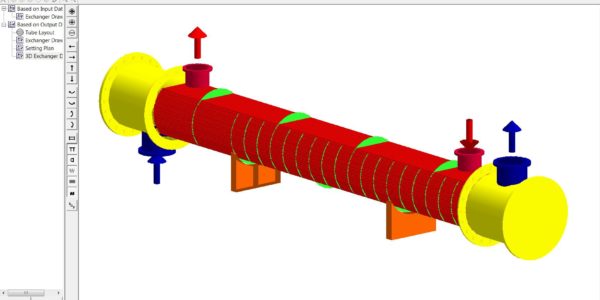

Thermal design calculations and vibrational analysis of all types of Heat Exchangers using Heat Transfer Research, Inc. (HTRI) software.

-

05

Services for a global network of creators.

Engineerings

We are well versed with all stringent requirements and specifications of our esteemed clients and their respective end users.

DESIGN CODES & STANDARDS

- ASME SEC. VIII DIV 1 & 2

- ASME SEC. I

- EN 13445

- PED 2014/68/EU / CE MARKING

- TEMA

- IBR

- AD-2000 MERKBLATT HP

- GOST/TR CU- RUSSIA

WORKSHOP OVERVIEW

Our world class unit VITECH HEAVY EQUIPMENTS PVT. LTD. is spread over an area of 55,000 Sq.mtr

Currently, having 2 covered bays 22 mtr. X 120 mtr. dedicated for stainless steel & carbon steel with EOT overhead cranes of (35 T + 5 T) - 4 nos. & (15 T)- 2 nos. & an open yard of 45 mtr. X 65 mtr. with Goliath cranes of 25/5 T – 1 no. & for inter-bay material movement material transfer cars of 25MT – 2 nos. & 5 MT – 1 no. The facility also has spacious 8 Mtr. x 8 Mtr. wide entrance doors.

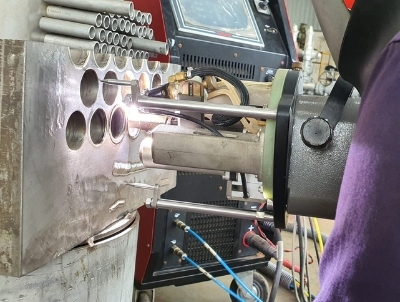

We have a provision for future expansion for another 3 bays of 22 Mtr. X 120 Mtr. Currently expansion is under process. We are expanding 1 bay of 22 Mtr X 120 Mtr and 03 Huge modular fabrication yard approx. 12000 Sq mtr. This new expanding bays equipped with high capacity EOT cranes such as 50 MT / 10 MT – 02 Nos, 35 MT – 02 Nos & 15 MT – 03 Nos. We have the capability of manufacturing equipment up to 125 mm thickness with In-house facilities such as 3000 mm x 125 mm thk. Imported plate bending m/c, CNC Plasma cutting m/c (80 mm thk. for S.S. & 200 mm thk. for C.S.), Hydraulic power press, automated pipe spool welding system, Tube to tube welding head, orbital welding m/c, Modular heat treatment facility, Machining shop, Blasting & Painting booth, Pickling and Passivation bath.

Our other 2 units VITECH EQUIPMENTS PVT. LTD. & VITECH FABRICATIONS PVT. LTD. has a total plot area of 3300 & 1000 sq. mtr with fully equipped covered bays having EOT cranes of (30 T + 5 T), (20 T + 5 T) & 10 Ton capacity. Our workforce consists of 250 + employees working 6 days a week and having a combined production capacity of 700 MT/Month. We have the capability to fabricate jobs up to 400 tons in single piece as the jobs can be handled & loaded using lifting jacks. The unit is designed to accommodate separate bays for Stainless Steel & Carbon steel.

Currently, having 2 covered bays 22 mtr. X 120 mtr. dedicated for stainless steel & carbon steel with EOT overhead cranes of (35 T + 5 T) - 4 nos. & (15 T)- 2 nos. & an open yard of 45 mtr. X 65 mtr. with Goliath cranes of 25/5 T – 1 no. & for inter-bay material movement material transfer cars of 25MT – 2 nos. & 5 MT – 1 no. The facility also has spacious 8 Mtr. x 8 Mtr. wide entrance doors.

We have a provision for future expansion for another 3 bays of 22 Mtr. X 120 Mtr. Currently expansion is under process. We are expanding 1 bay of 22 Mtr X 120 Mtr and 03 Huge modular fabrication yard approx. 12000 Sq mtr. This new expanding bays equipped with high capacity EOT cranes such as 50 MT / 10 MT – 02 Nos, 35 MT – 02 Nos & 15 MT – 03 Nos. We have the capability of manufacturing equipment up to 125 mm thickness with In-house facilities such as 3000 mm x 125 mm thk. Imported plate bending m/c, CNC Plasma cutting m/c (80 mm thk. for S.S. & 200 mm thk. for C.S.), Hydraulic power press, automated pipe spool welding system, Tube to tube welding head, orbital welding m/c, Modular heat treatment facility, Machining shop, Blasting & Painting booth, Pickling and Passivation bath.

Our other 2 units VITECH EQUIPMENTS PVT. LTD. & VITECH FABRICATIONS PVT. LTD. has a total plot area of 3300 & 1000 sq. mtr with fully equipped covered bays having EOT cranes of (30 T + 5 T), (20 T + 5 T) & 10 Ton capacity. Our workforce consists of 250 + employees working 6 days a week and having a combined production capacity of 700 MT/Month. We have the capability to fabricate jobs up to 400 tons in single piece as the jobs can be handled & loaded using lifting jacks. The unit is designed to accommodate separate bays for Stainless Steel & Carbon steel.

Manufacturing Capability

Huge open yard of 12000 Sq. Mtr. with a 34 Mtr. span Double Girder Goliath crane for Big Size Skid Modules weighing upto 400 tons. Below table is a summary of the capability of manufacturing by VITECH in terms of max. weight, length & diameter.

Over the years our design & manufacturing team is well versed in various ferrous & nonferrous material.

Automation Systems at Vitech Equipments

We have the latest Advanced Automated Systems which gives us an edge over our competitors in the manufacturing of Equipments such as Cladded & Non-Cladded Heat exchangers, Pressure vessels, Process Skid Modules & Pre-fabricated Piping Spools for our International Clients requiring high quality manufacturing standards in special materials such as Cladded steel, Carbon steel, Alloy steel, Stainless steel, 6 % moly, Super-Duplex, Duplex & Titanium.